Wet grinding and milling with a plus. N4+

The best seller, plus extra cooling.

The essence of wet grinding

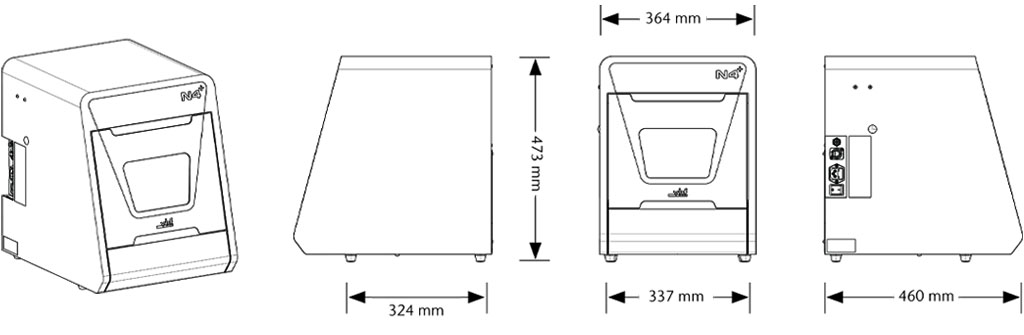

Thanks to its striking, updated look, the new N4+ is an eye-catching choice in any laboratory. We have also equipped it with a water-cooled spindle. That means you benefit from improved process stability, and you can always rely on first-class results even in continuous operation.

8

Tools

3

Blocks

0

Discs

4

axes

The essence of wet grinding

The N4+ is an efficient wet processing machine for grinding and milling glass ceramic, composite, and zircon blocks, as well as CoCr and titanium abutments. It impresses not only thanks to its high precision and fast drives, but also thanks to its ultra-compact housing with closed fluid circuit. Eight fine nozzles on the spindle direct the cooling liquid precisely onto the effective area between the tools and workpiece, delivering an optimal cooling effect.

The essence of wet grinding

The N4+ is an efficient wet processing machine for grinding and milling glass ceramic, composite, and zircon blocks, as well as CoCr and titanium abutments. It impresses not only thanks to its high precision and fast drives, but also thanks to its ultra-compact housing with closed fluid circuit. Eight fine nozzles on the spindle direct the cooling liquid precisely onto the effective area between the tools and workpiece, delivering an optimal cooling effect.

The essence of wet grinding

The N4+ is an efficient wet processing machine for grinding and milling glass ceramic, composite, and zircon blocks, as well as CoCr and titanium abutments. It impresses not only thanks to its high precision and fast drives, but also thanks to its ultra-compact housing with closed fluid circuit. Eight fine nozzles on the spindle direct the cooling liquid precisely onto the effective area between the tools and workpiece, delivering an optimal cooling effect.

The essence of wet grinding

The N4+ is an efficient wet processing machine for grinding and milling glass ceramic, composite, and zircon blocks, as well as CoCr and titanium abutments. It impresses not only thanks to its high precision and fast drives, but also thanks to its ultra-compact housing with closed fluid circuit. Eight fine nozzles on the spindle direct the cooling liquid precisely onto the effective area between the tools and workpiece, delivering an optimal cooling effect.

The essence of wet grinding

The N4+ is an efficient wet processing machine for grinding and milling glass ceramic, composite, and zircon blocks, as well as CoCr and titanium abutments. It impresses not only thanks to its high precision and fast drives, but also thanks to its ultra-compact housing with closed fluid circuit. Eight fine nozzles on the spindle direct the cooling liquid precisely onto the effective area between the tools and workpiece, delivering an optimal cooling effect.

The essence of wet grinding

The N4+ is an efficient wet processing machine for grinding and milling glass ceramic, composite, and zircon blocks, as well as CoCr and titanium abutments. It impresses not only thanks to its high precision and fast drives, but also thanks to its ultra-compact housing with closed fluid circuit. Eight fine nozzles on the spindle direct the cooling liquid precisely onto the effective area between the tools and workpiece, delivering an optimal cooling effect.

Exceptional precision

Restorations in Ultra HD

Premium spindle with four-fold ball bearing made of hybrid ceramic for the highest concentricity

3 μm repetition accuracy

Exceptional precision

Restorations in Ultra HD

Premium spindle with four-fold ball bearing made of hybrid ceramic for the highest concentricity

3 μm repetition accuracy

Exceptional precision

Restorations in Ultra HD

Premium spindle with four-fold ball bearing made of hybrid ceramic for the highest concentricity

3 μm repetition accuracy

Exceptional precision

Restorations in Ultra HD

Premium spindle with four-fold ball bearing made of hybrid ceramic for the highest concentricity

3 μm repetition accuracy

Exceptional precision

Restorations in Ultra HD

Premium spindle with four-fold ball bearing made of hybrid ceramic for the highest concentricity

3 μm repetition accuracy

Did you know?

vhf has been using high-quality 4-fold hybrid ceramic bearings for over ten years, particularly for machining metals. For you, this means a significantly longer spindle service life, higher surface quality and noticeably better accuracy of fit.

You choose: material, manufacturer, indication

All common block materials up to 45 mm in length and even abutments